OEM Instructions

Since its founding, Jiarui Innovation has been dedicated to the manufacturing and OEM services of high-tech adhesive tapes and film products. We have continuously focused on the development of specialized solutions, particularly in silicone tapes, polyimide (gold finger) masking tapes, acrylic tapes, high-temperature thermal spray masking tapes, specialty labels and protective films, release liners, and fluorinated release films.

With over 20 years of professional experience, we are committed to delivering accurate and efficient tailor-made solutions for our customers. Below is an overview of our complete OEM service process:

With over 20 years of professional experience, we are committed to delivering accurate and efficient tailor-made solutions for our customers. Below is an overview of our complete OEM service process:

Product Design

Our collaboration with clients begins with a thorough discussion of their requirements. Our expert team first gains a deep understanding of the product’s intended use, functional needs, and any specific requests. Based on this information, we provide professional recommendations and assist in designing product specifications that best meet the client's needs — laying a solid foundation for sampling and future production.

01

Quotation and Sample Production

Once the design is finalized, we proceed with an initial quotation and sample production based on the selected materials and design specifications. During this stage, we ensure that the sample meets the client’s functional and quality requirements before submitting it for customer approval. Upon successful prototyping and client confirmation, we move forward with order processing and mass production.

02

Mass Production

Once the quotation and sample are confirmed, we officially move into the mass production stage. Equipped with advanced manufacturing equipment and mature production processes, we are capable of delivering efficient and stable large-scale production. Each production batch is strictly controlled to ensure consistent quality that meets international standards.

03

Quality Control

During the production process, we conduct strict quality inspections on every batch to ensure all products meet high-quality standards. From raw material selection to final product testing, our quality management team oversees every step to guarantee that each product delivered to our customers is flawless.

04

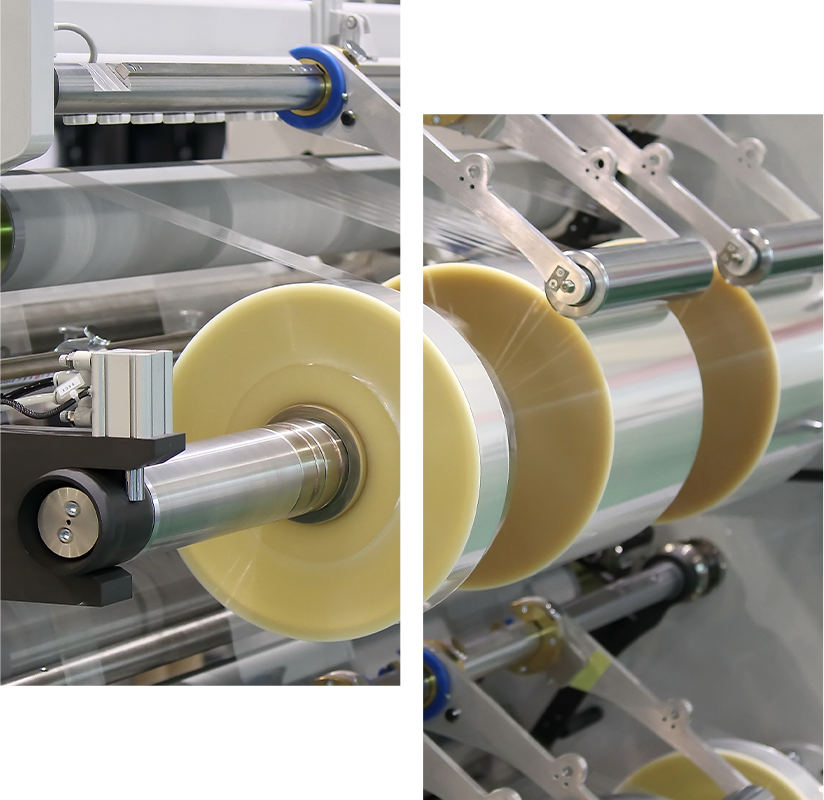

Processing and slitting (Rewinding or Cutting)

Based on the specific needs of our clients, we offer a variety of post-processing options, including rewinding and slitting services. These processes can be customized to accommodate different sizes and shapes, meeting the requirements of various specialized applications and ensuring that each product fully aligns with the customer's intended use.

05

Packaging

To ensure product safety and stability during transportation, we carefully package and palletize each production batch. Customized packaging solutions are available, and we select appropriate packaging methods based on the characteristics of each product to prevent any damage during transit.

06

Shipping

Finally, products are shipped and delivered according to the customer’s requirements, ensuring timely and secure arrival at their destination. We also provide full tracking services, allowing customers to monitor the shipment status at any time — delivering worry-free, end-to-end support.

07